Home » Technology » Subtractive Manufacturing

Subtractive

Manufacturing

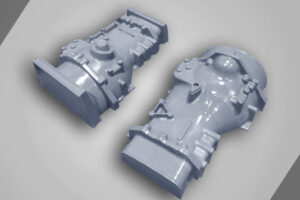

Subtractive Manufacturing in the casting domain involves machining of solid sand blocks to form a mold or manufacturing patterns to make molds. Depending on the volume requirement sand molds can be milled for small quantities or bigger molds. Higher volume requirements can be met by conventional molding through patterns.

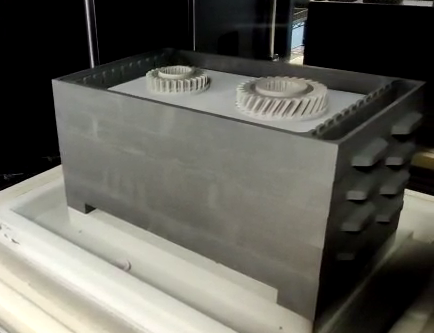

Mold Milling

Considering the time constraints in rapid Prototype development where a single piece or small batch is required, the hybrid manufacturing process is adopted, where the Molds are Directly Milled and Cores are 3D Sand Printed. This provides cost effective and timely solutions especially for larger Prototypes.

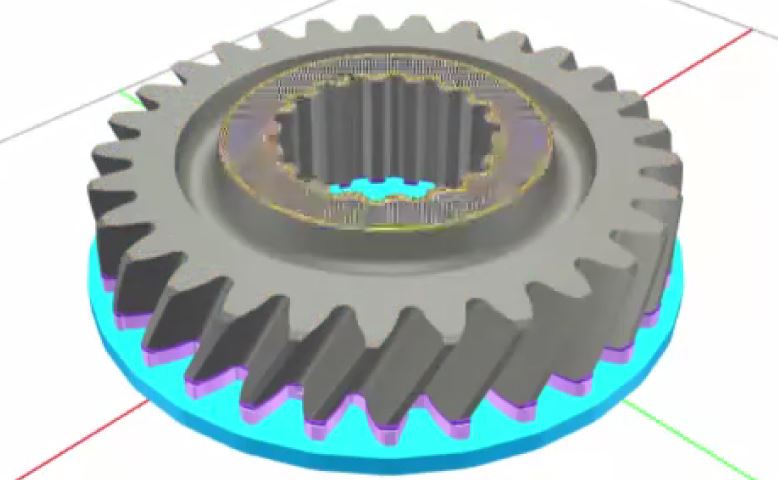

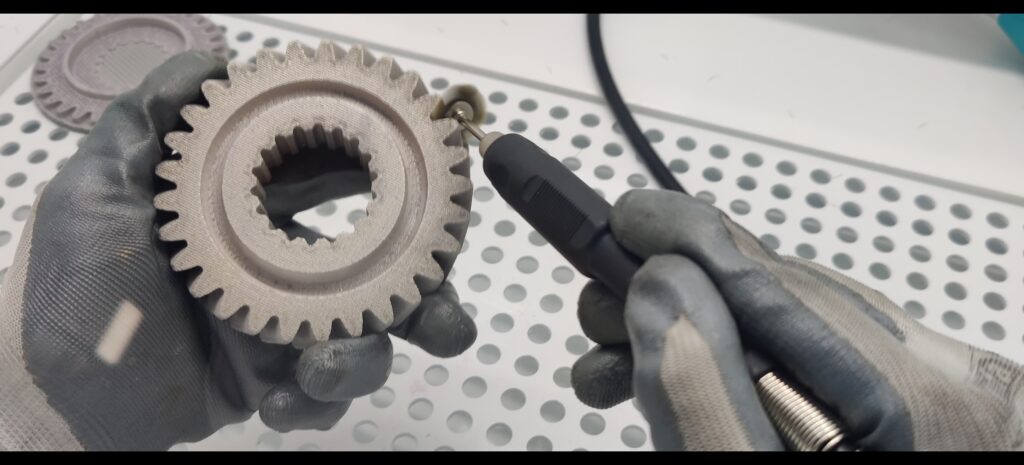

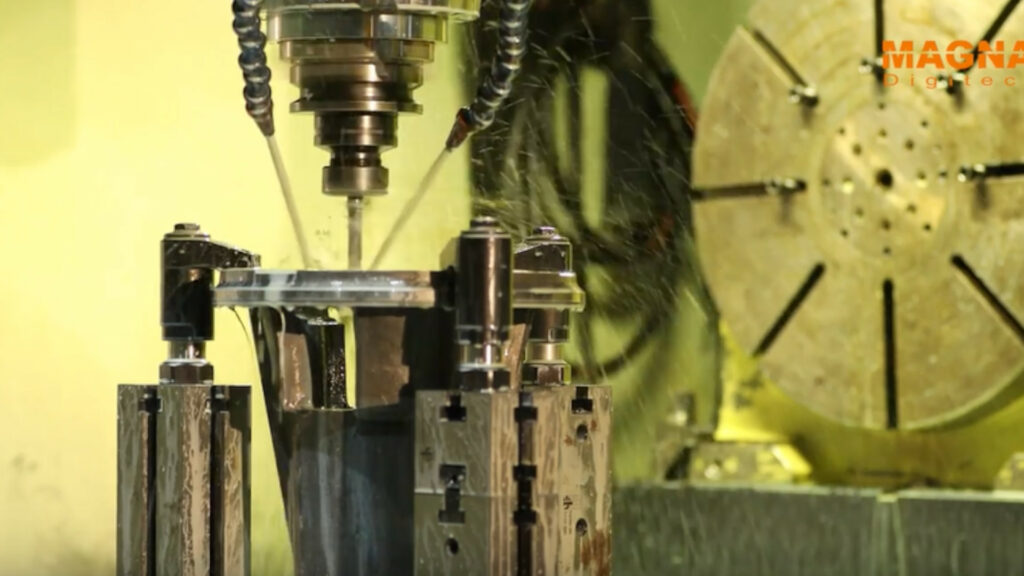

Pattern Making

Magna Digitech’s expertise in designing and manufacturing over 4000+ castings has given us the in-depth experience for pattern designing, this includes draft angles, shrinkage allowances etc. Our FlexiCAM 3D Router (2000×3000 mm) gives us the ability to quickly manufacture the patterns in-house with great accuracy and fidelity.