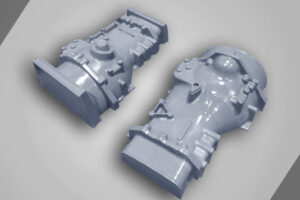

Subtractive Manufacturing in the casting domain involves machining of solid sand blocks to form a mold or manufacturing patterns to make molds. Depending on the volume requirement sand molds can be milled for small quantities or bigger molds. Higher volume requirements can be met by conventional molding through patterns.