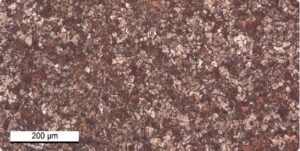

17-4 ph stainless steel

17-4 PH stainless steel is a precipitation hardening steel used in a wide range of industrial applications including those with mildly corrosive environments and high-strength requirements.

Applications

- Manufacturing machinery

- Chemical processing

- Food processing

- Pump components

- Valves

- Fasteners

- Jigs and fixtures

3D Printing Software :

3D Printing Software :

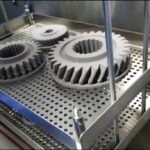

Dictated by software, this is the physical process by which the 3D printers deposit material layer-by-layer in the shape of a part. The specifics of this process impact part quality, precision, and print time

Dictated by software, this is the physical process by which the 3D printers deposit material layer-by-layer in the shape of a part. The specifics of this process impact part quality, precision, and print time

Sintering :

Sintering :