Component inspection

Metallurgical testing

Spectro Analyser

SPECTROLAB Spectrometer capable to test 30 elements to ensure that the Rapid Prototype meets BSI and customer standards , before every metal melt is poured.

Image Analyser

Carl Zeiss Micro Analyzer with a scope of 50 to 400x and Clemax Image analyzer to ensure that material received proper processing treatment and has the specified spheroidization, grain size etc,.

Dimensional inspection

Blue Ray Scanner

Romer Portable CMM with 3D Scanner (Measuring Envelope 2000mm).

- 6 Axis absolute Arm with high accuracy Absolute encoders and Spin Grips.

- Profile surfaces can be scanned and compared with 3D Model.

- Reliable measurement results compared to manual layout inspection.

Coordinate-measuring machine (CMM)

- Fully Automatic Brown & Sharpe CMMs of

- Table Size 1200 x 2200 x 1000 mm

- Table Size 800 x 1000 x 600 mm

- Trimos 2D Measuring machine for measurement

- Mitutoyo Manual CMM of Table Size 500 x 700 x 400 mm

Non Destructive Testing

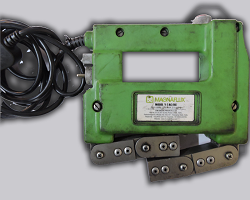

Magnetic particle and Dye Penetrant inspection

To ensure that the components are from defects like fatigue cracks and surface-breaking defects in non-porous materials, magnetic particle (Magna Flux Y-7) and dye penetrant inspection is used to find surface and sub-surface indications .

x-ray inspection and ULTRASONIC TESTING

X-ray inspection is outsourced to identify internal defects. Ultrasonic testing devices to determine internal discontinuities