With our Engineering Design and expert Casting Simulation capabilities, we have carved a unique niche for ourselves in the Foundry Engineering Services. We have a proven track record of building over 10,000 Solid Models from legacy drawings and Simulation of over 4000 Components for the manufacture of high integrity castings. Read More..

Engineering And

Manufacturing Technology

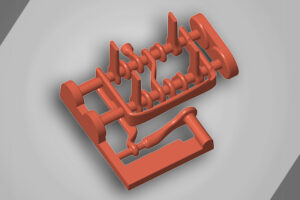

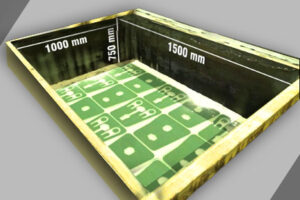

Our Additive Manufacturing process with 3D printing system designed to manufacture Mold and Cores for Sand Casting foundries, facilitating for the creation of complex Sand Molds and Cores directly from CAD data without the need for a physical pattern. The 3D Sand Printer allows producing Cores and Molds for low volume work and Prototypes without producing expensive and time-consuming tooling for customers. Read More..

Direct Metal printing is a futuristic technology that produces impossible-to-make parts directly from your CAD data. Advantages to this process include the ability to produce strong, complex geometries, internal lattice structures, conformal cooling channels and other features that cannot be made with traditional machining.

Parts can be made quickly with a minimum of material waste making them ideal for next-generation engineering in aerospace, medical, automotive and other industries.

Considering the time constraints in Rapid Prototype development where a single piece or small batch is required, The hybrid manufacturing process is adopted, where the Molds are directly Milled. This provides cost effective and timely solutions especially for larger prototypes. Read More..

Our Machining capabilities allows us to deliver certified ready to assemble Prototype Components in a timely manner. This is achieved through our Machining Simulation Capabilities, Modular fixtureing and Computerized CMM systems. With over 24 CNC machines including 5-Axis capabilities the appropriate machines are available for different Components.. Read More..

Magna Digitech

Casting With Technology