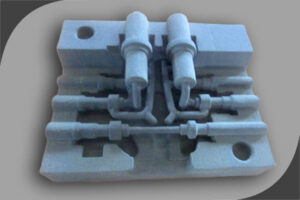

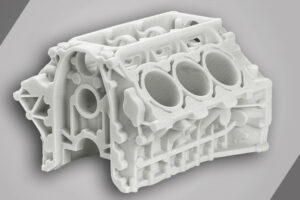

By our expertise in engineering and Computer Aided Designing moving ahead a step forward we at Magna Digitech have adopted innovative Additive Manufacturing technology to enhancing our Rapid Prototyping capabilities. The 3D printing technology provides a transformative approach to industrial manufacturing that enables us to create prototypes of any complicated geometry in days.