Home » Technology » Casting Engineering

Casting

Engineering

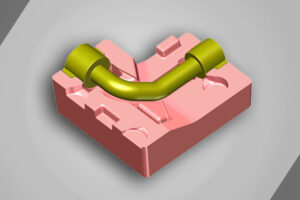

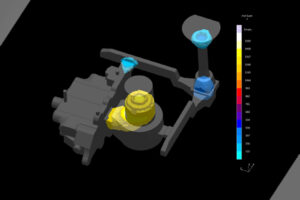

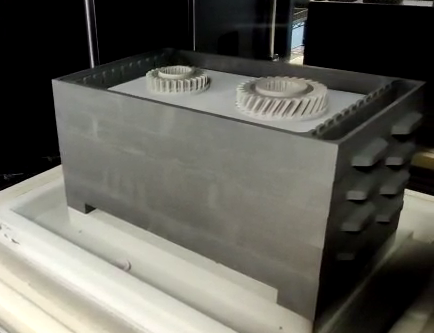

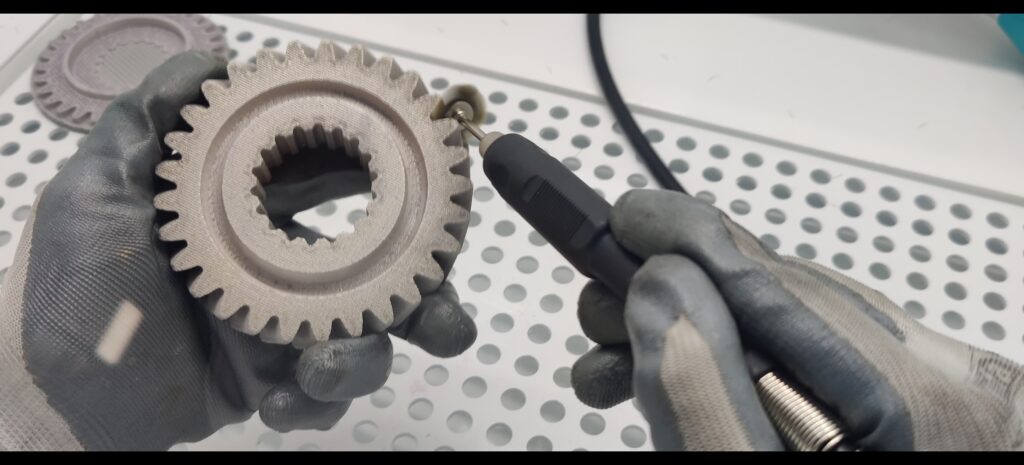

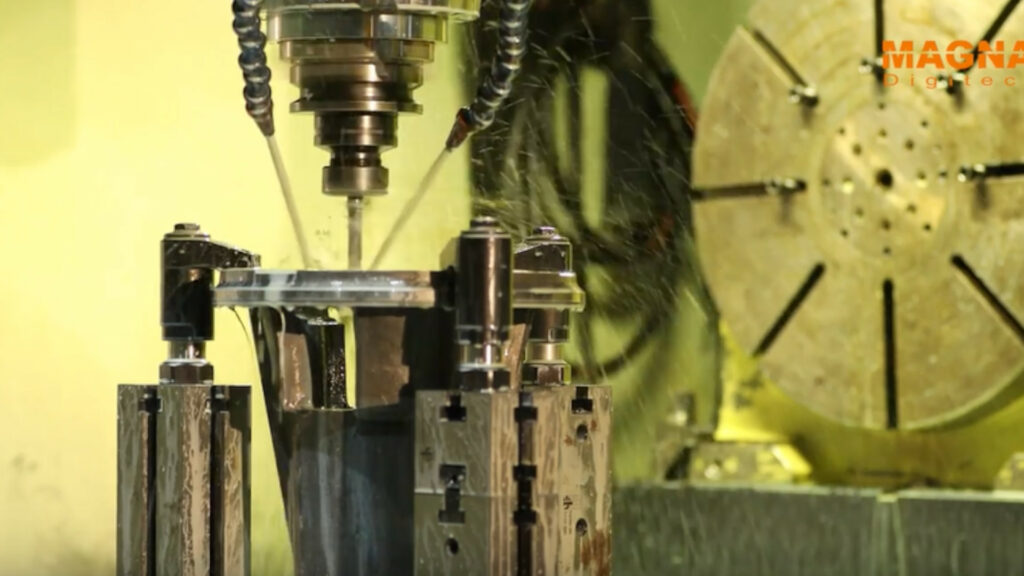

Our Technology Portfolio allows us to iterate quickly considering several variables like Design-Optimization, Quality-Benchmarks, Cost-Effectiveness to convert your design concept into reality. With the benefits of cost-effective Metal Casting Design, our customers can reduce the rejections rates ultimately and have a high yield rate. We design a functionally, stable cast product. The stages involve a thorough analysis of design, and castability with our Casting Simulation Service, which plays a prominent role in the Casting development cycle.

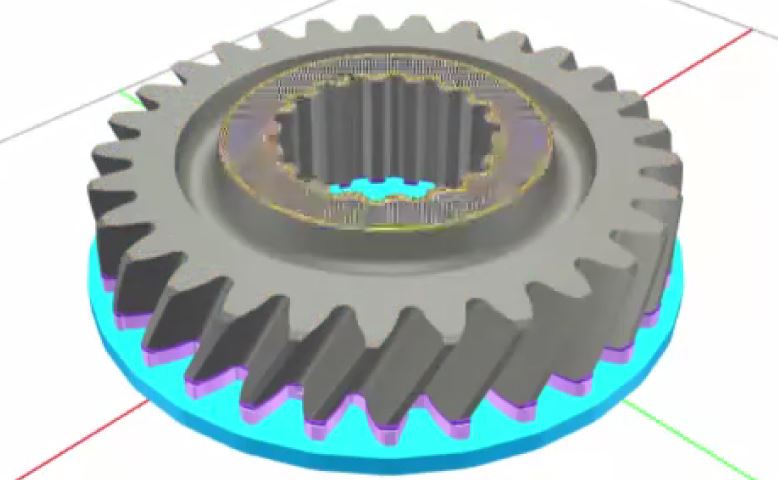

As modern manufacturing requires software expertise to design Prototypes, Magna Digitech delivers expert Casting Design services giving you a robust Casting Design. Our Design services enable you to reverse engineer your legacy developments, and converting your complex fabrications to simplified Casting Designs. Read More..

At Magna Digitech, we have more than 2 decades of Casting Simulation experience making use of cutting-edge Simulation software to perform Casting Simulation before producing expensive Molds or Patterns to analyze the cast metal flow and solidification inside the cavities, making the casting development and manufacturing more precise and quicker. Our customers benefit from reduced rejection, increased yields, trouble less casting process. Read More..

Powered By The cutting edge Software Technologies

All the above are the Trade Marks of the Registered Owners